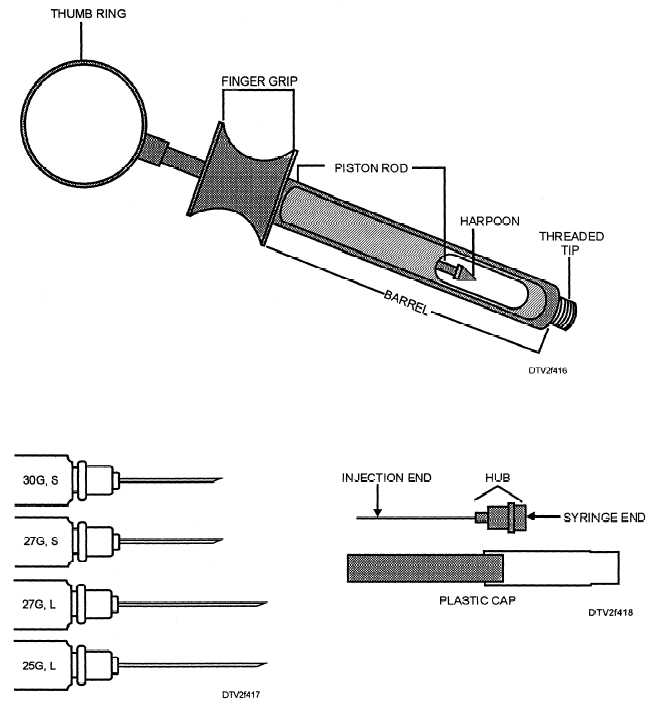

Figure 4-16. - Parts of an aspirating syringe.

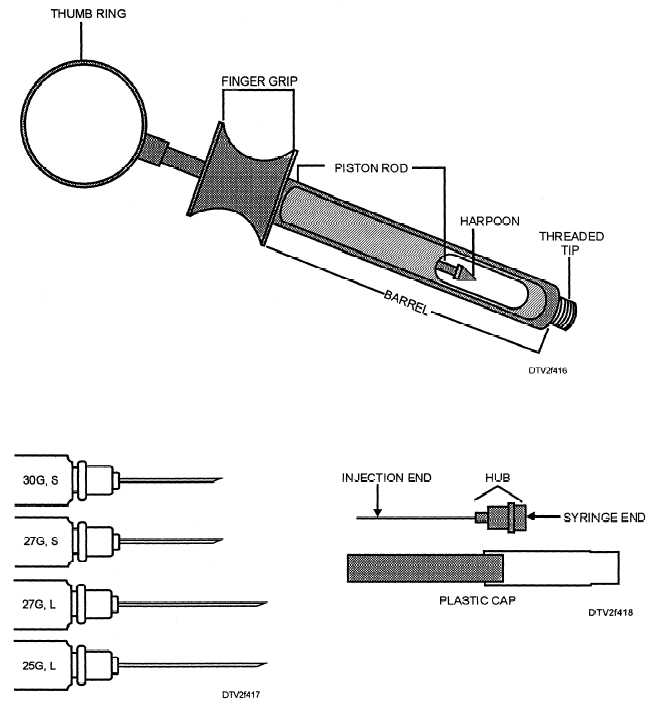

Figure 4-17. - Different gauges and lengths of aspirating syringe needles.

Rubber Dam Punch

The rubber dam punch is used to make necessary spaced holes in the rubber dam material. The working end is designed with a plunger on one side and a wheel on the other side (fig. 4-19). This wheel has different sized holes on the flat surface facing the plunger. These features let the operator select and adjust the wheel to punch the desired diameter hole in the rubber dam.

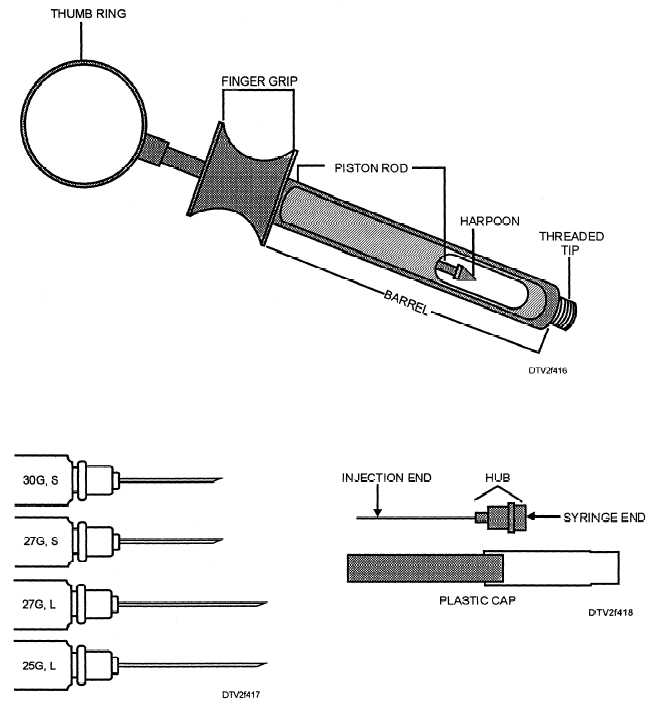

Figure 4-18. - Parts of the aspirating syringe needle.

Figure 4-19 also illustrates the recommended holes on the wheel to use. The largest hole is used on the tooth that your clamp will go on. The last five remaining holes correspond to the teeth that are included in the isolation.

Rubber Dam Clamps

After the required number of holes are punched in the rubber dam, it is stretched to fit over each designed tooth. To maintain a snug fit around the neck of the

Continue Reading