a disinfecting solution, allow them to soak, and then scrub them under water to avoid generating splatter.

PRESTERILIZATION PROCESSING

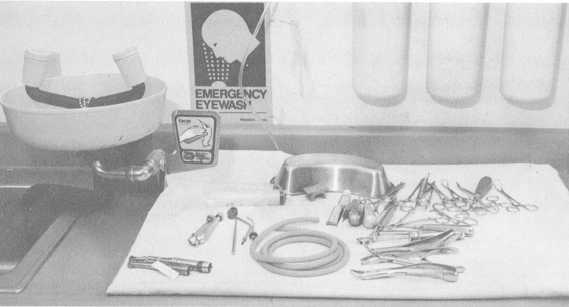

You are still in the processing area of the CSR and have just finished cleaning your instruments using one of the three methods of cleaning discussed previously and letting them dry as shown in figure 10-5. Perform the following procedures in the sterilization process next.

Inspection and Sorting of Instruments

After drying, you must inspect items closely for wear, breakage, and cleanliness. Sort instruments according to sets or packs. This is the prestaging area where your instruments are sorted before wrapping and packaging.

Wrapping and Packaging

Wrapping and packaging is the last step just before the sterilization process. Many different types of sterilizers, packaging, and wrapping materials are used in the CSR.

Before terminal (final) sterilization, wrap or package all critical and semicritical items individually or in sets. Ensure you place consumable supplies (fig. 10-6) that are required by your command in each particular pack before wrapping such items as needles, cotton rolls and pellets, gauze, aluminum foil for dental light handles, internal indicators, and towels.

Dental instruments are usually placed in packs, on trays or cassettes, before placing them into the sterilizer. The most common wrapping materials and containers are paper, paper/plastic, nylon tubing, and cloth. Aluminum foil, closed metal trays, and perforated cassettes may also be used. The packaging or wrapping materials that you select depends on the compatibility of what type of sterilization method you are using. Table 10-1 shows various sterilization packaging materials and their suitability to withstand steam or dry heat sterilization. Always refer to the sterilizer manufacturer's instructions for suitability.

Paper materials are available in the form of bags or flat disposable wraps. Both types are sealed with adhesive indicator tape. The combination paper/ plastic peel packs (fig. 10-7) are available in varied sizes of preformed bags or rolls of varied widths that can be cut to the desired length. Either type can be sealed with the adhesive indicator tape or self-sealed.

Heat sealed plastic or nylon tubing should only be used as an overwrap after the pack has been sterilized. Heat sealed overwrapping will extend a 30 day shelf life to 180 days.

Figure 10-5. - Instruments drying in the processing area.

Continue Reading