CHAPTER 10 STERILIZATION AND DISINFECTION

Concerns about transmitting infectious agents, such as hepatitis virus (HBV) and human immunodeficiency virus (HIV), have caused the dental community to become more aware of the need to sterilize and disinfect instruments, materials, and other equipment to protect providers and patients. In this chapter, we will explain the sterilization and disinfection process with which you, as a dental assistant, will be involved. We will also give you an overview of the procedures so you can effectively carry out your duties.

The highest level of contamination control is sterilization because it results in the total destruction of all forms of microbial life. A variety of sterilization methods and many types of liquid chemical disinfecting agents are available. Heat sterilization is preferable for all equipment and materials that can withstand high temperatures. Heat sterilization is effective, relatively easy to use, comparatively inexpensive, and readily monitored for effectiveness. Sterilization and the availability of sterile products for use in dental healthcare delivery depend on many factors. The most critical factors are as follows:

Proper and efficient sterilization facility design

Sound infection control practices before, during, and after sterilization

The effectiveness of the actual sterilization process

PHYSICAL DESIGN

Dental Treatment Facilities (DTFs) must have a central sterilization room (CSR) or a central sterilization area. Centralization of sterilization activity is safer, provides more efficient use of materials and personnel, and standardizes execution and monitoring procedures. We will explain the critical design elements that make up a CSR area next.

Dedicated Work Areas

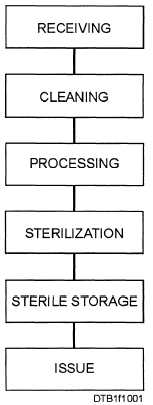

The design and outfitting of a sterilization area must include work areas for receiving, cleaning, processing, sterilizing, storing, and issuing of instruments and equipment.

Functional Flow of the Sterilization Process

Most large dental clinics will have a permanent CSR technician assigned to the sterilization area. As part of your indoctrination, you may be temporarily assigned in the CSR so you can learn your command's sterilization processes. All CSRs should have a functional flow system where equipment, instruments, and materials are first introduced into the receiving area, and work their way through to the issue area in a specific order. Figure 10-1 illustrates a CSR functional flow chart that all personnel should adhere to while working in the CSR. Once you are physically in an area of the CSR, you must not go backwards or skip an area. This will compromise the entire sterilization process. Do not process contaminated instruments, materials, or equipment in an area that may contaminate the sterilized items.

Figure 10-1. - CSR functional flow chart.

Continue Reading