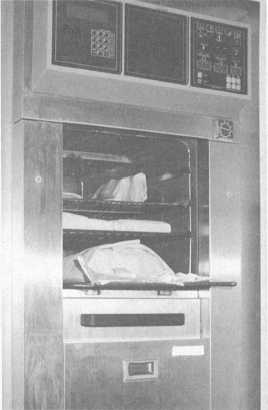

Figure 10-11. - Prevacuum steam sterilizer.

Dry heat is suitable for sterilizing metal instruments that rust or dull in the presence of water vapor. A disadvantage is that the high temperatures destroy many rubber and plastic based materials, melt the solder of most metal impression trays, and weaken some fabrics, as well as discolor other fabrics and paper materials.

A complete cycle involves heating the dry heat oven (fig. 10-12) to the appropriate temperature and maintaining that temperature for the proper time interval. Depending on the location, dry heat ovens can use one of the following heating elements to achieve sterilization:

Conduction (direct contact with a heat source)

Radiation (long electromagnetic waves)

Convection (heated air)

Because dry air is not as efficient a heat conductor as moist heat at the same temperature, a much higher temperature is required for sterilization. One of the most common problems with the use of dry heat sterilization is the failure to properly time the exposure. A typical dry heat cycle is 90 minutes at 320-345°F, plus the time required to preheat the chamber before beginning the sterilization cycle. A common misuse of the dry heat method occurs when the oven door is opened, and an instrument is quickly removed during the timed cycle. This interrupts the cycle and timing must begin all over again.

Advances in the design of the dry heat oven resulted in the development of the dry heat convection unit, which uses forced air at higher temperatures. This method of rapid heat transfer achieves sterilization in 12 minutes at 375°F (190°C) for wrapped items and in 6 minutes for unwrapped items. Biological monitoring will be performed weekly. Consult the manufacturer's instructions of each type of dry heat sterilizer for specific details on its operation and user maintenance.

Chemical Vapor Sterilization

This process uses a mixture of chemicals, including alcohol, formaldehyde, ketone, acetone, and water, that are heated under pressure to form a sterilizing gas. Sterilization requires 20 minutes at 270°F with 20 psi when instruments are either unwrapped or bagged following the manufacturer's instructions. 10-12